The role of vacuum technology in the field of freeze-drying

2024-10-29 14:30There are many ways to extend the shelf life of food. An important step in the oldest smoking and curing methods is drying, and this method has been around long before freezing, high temperature cooking or vacuum packing. Modern freeze-drying technology is an improved distillation of traditional drying methods, which can prevent food deterioration for a longer period of time. This process is only possible with modern vacuum technology, as freeze-dried foods need to be carried out under vacuum.

Freeze drying is suitable for fruits and berries, but also for cooked meat or vegetables. Herbs and spices can also be preserved by freeze-drying, with only a few percent of moisture remaining in these products after treatment. The most famous freeze-dried food is probably soluble (instant) coffee. Many ready-to-eat foods that dissolve only in boiling water and have been made into pellets or powders are also freeze-dried. In general, food can also be dried in a simpler way, such as drying. But the drawback is that it may change the structure and appearance of the food, in addition, the aroma will react with the oxygen in the atmosphere, affecting the taste.

The freeze-drying process does not change the structure of the food, and the dried food cells can easily reabsorb water during cooking. By vacuum drying, the fragrance is preserved as much as possible.

Freeze-drying is a pure physical process using the principle of sublimation. In the vacuum of the drying chamber, the frozen water sublimates to water vapor. Ice skips "liquid" and goes straight from "solid" to "gas."

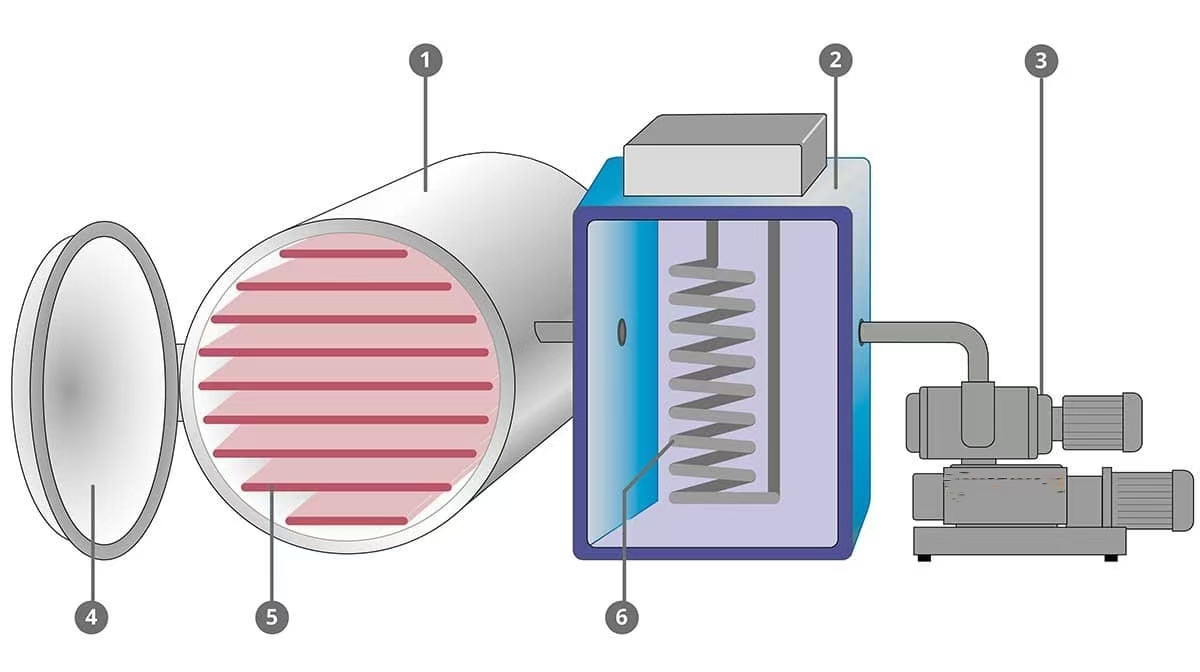

Freeze-dryer schematic: 1. Drying chamber, 2. Condenser (cold trap), 3. Vacuum system, 4. Open the gate, 5. Can heat the intermediate plate, 6. Cool the coil.

In fact, before the drying process can begin, whether it is berries, fruit slices or coffee extracts, they must be refrigerated at low temperatures in the cold room. The product is therefore laid out on a pallet and placed directly or on a trolley in the freezer, after which the frozen product is placed in the drying chamber.

In some freeze-dryers, freezing can be done directly in the drying chamber, and freeze-dryers are also used for continuous processing of food.

After cooling, the actual drying process is carried out in the chamber, where the air pressure is reduced by a vacuum pump until a vacuum of 1 to 0.5 mbar is reached. Now, the frozen water begins to evaporate at a low temperature of -50 to -40 ° C, and the water vapor is pumped from the drying chamber to the downstream condenser by the vacuum pump. In this "ice trap", which is cooled to at least -70 ° C, the water vapor sublimates on the cooling coil to condense into ice, and in this process, most of the water in the product is removed, which is called preliminary drying.

As the water sublimes, it absorbs heat energy from the drying chamber, which means that during the process, the temperature in the chamber drops, so the chamber needs to be heated. Care must be taken to ensure that only the same heat energy as the sublimation energy obtained from water is added to keep the temperature constant or allow the temperature to rise slightly to -20 ° C.

For most foods, primary drying is immediately followed by secondary drying. This includes removing residual moisture in the product in a strongly adsorbed state by reducing the vacuum to 0.01 mbar or less and raising the temperature above freezing. The drying chamber is then ventilated to atmospheric pressure and the dried product with a water content of 1-4% is removed for further processing. The use of dry air or inert gas for ventilation, so that the dried product can not absorb moisture in the ambient air.