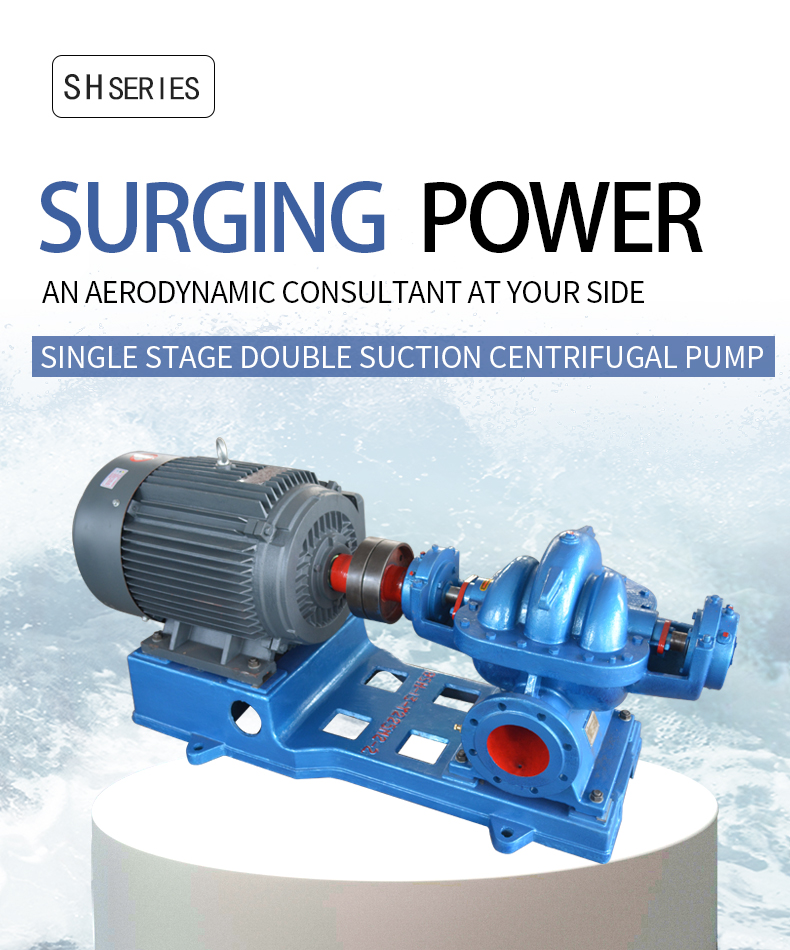

Single Stage Double Suction Split water pump

Our pumps have a wide variety, diverse styles and excellent quality. You can get the latest price and product information by sending an email.

- Jiekesen

- China

- 15-25 Working Days

- Factory Direct Supply

- Information

About Us

Single Stage Double Suction Split water pump

Product introduction

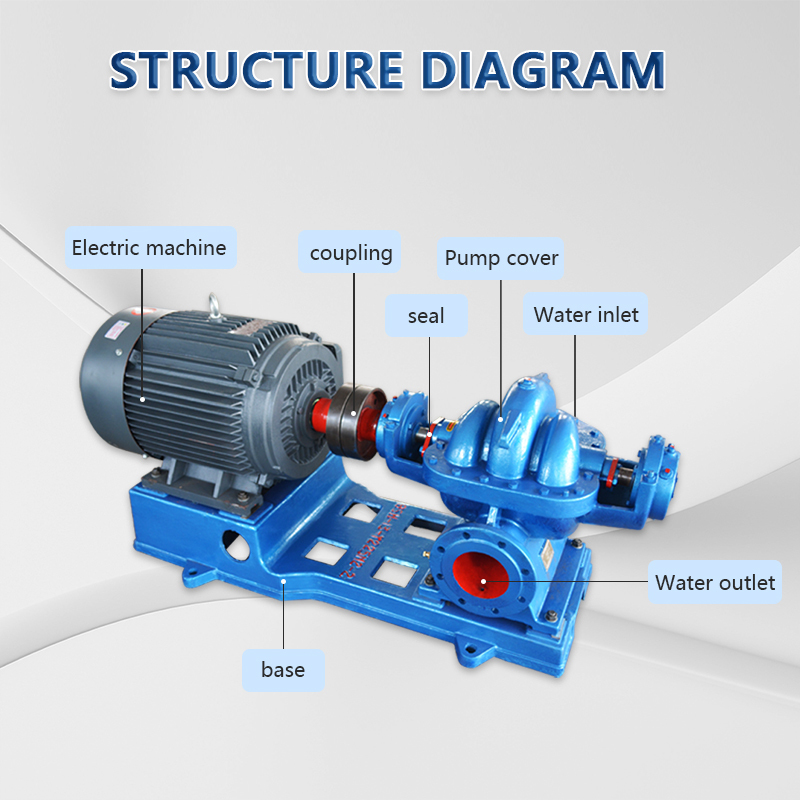

SH series and S series are single-stage, double suction, horizontal split centrifugal pumps, which are suitable for transporting non corrosive (or weak corrosive) liquid in Qingshuihe. The maximum temperature of the medium is 80 ℃, and the hot water below 130 ℃ can be delivered after the cooling water is introduced into the bearing bodies at both ends. The muddy water containing mud and sand can be transported by changing the manufacturing materials of sealing ring, shaft sleeve and impeller; By changing the material of the pump body and cover, the inlet pressure of the pump can be increased, which can be used in closed circulation occasions such as air conditioning and heating. Copper impeller and copper sealing ring are used to transport oil.

The shaft seal of the pump adopts soft packing seal (graphite asbestos root or carbon fiber packing). According to the user's requirements, mechanical seal can also be used. From the motor direction, the water inlet of SH type water pump is on the left side (counterclockwise rotation); The water inlet of S-type pump is on the right side (clockwise rotation), and the rotation direction of the pump can be changed according to the user's requirements

Manufacturing materials: pump body, pump cover - cast iron or nodular cast iron, impeller - cast iron, nodular cast iron or cast copper, shaft - carbon steel or stainless steel.

SH single stage double suction horizontal split centrifugal pump

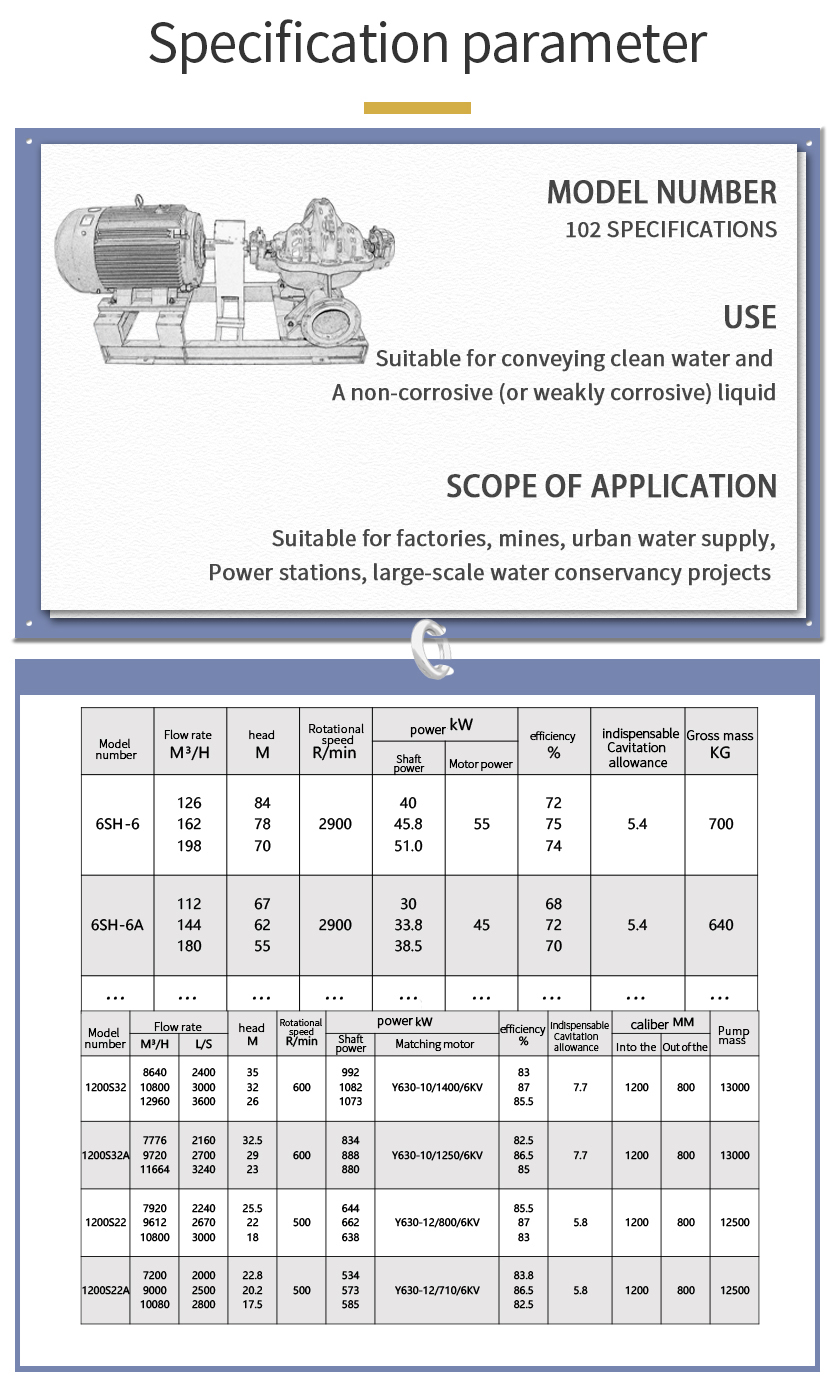

Parameter

After-sales instructions

After placing the order, please contact the salesperson to provide you with the installation plan as soon as possible. Please construct the foundation according to the dimensions on the foundation drawing.

2. Before installing and using the equipment, please carefully read the product installation and operation manual. If you have any questions, please call our 24-hour service hotline at 400-8570-567 or 13506440087. We will have professional technical personnel to coordinate with you.

3. Before leaving the factory, the equipment undergoes a water and pressure test. If there is a small amount of water stored in the pump and it is installed and used in colder areas, please ensure that the storage and installation environment of the pump will not cause the water in the pump to freeze. Improper storage causing pump damage will be the responsibility of the user. Please empty the equipment and pipelines in a timely manner when not in use in winter to avoid damage caused by frost

4. Before using the pump, please ensure that the power supply voltage is stable, there is a protective device (which can be matched with a control system), the environment is dry, and the pipeline valves are installed properly. If you have any questions about installation and use, you can call our factory's service hotline. Any damage to the pump caused by improper installation or use shall be the responsibility of the user.

6. It is recommended that you install a filtering device on the imported pipeline and regularly clean it to ensure the reliability and service life of the pump operation

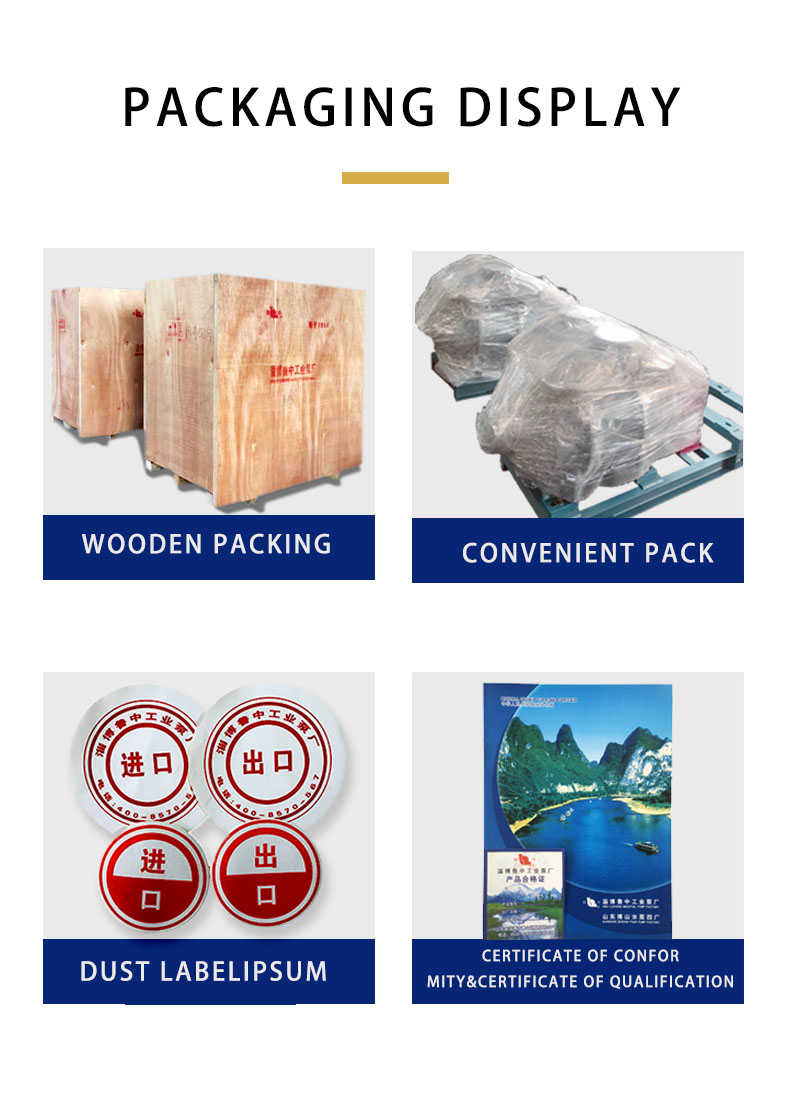

Receiving reminder

Dear customer, please check if the packaging of the goods is damaged upon receipt, and if the products, manuals, certificates of conformity, accessories, etc. are complete. If there are any abnormalities, please take photos immediately and contact the customer service manager. Please make sure to sign for it in person. Any loss or damage to the goods caused by not signing for it or not inspecting the goods will be the sole responsibility of the recipient.