2BV Series Liquid Ring Vacuum Pump

Our pumps have a wide variety, diverse styles and excellent quality. You can get the latest price and product information by sending an email.

- Jiekesen

- China

- 15-25 Working Days

- Factory Direct Supply

- Information

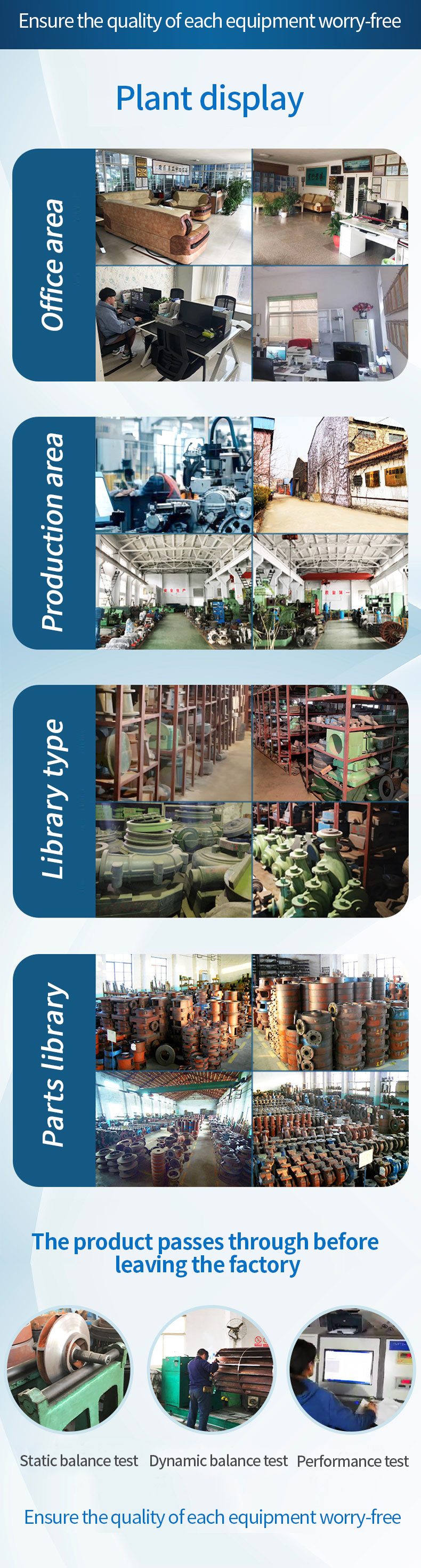

About Us

2BV Series Liquid Ring Vacuum Pump

Product introduction

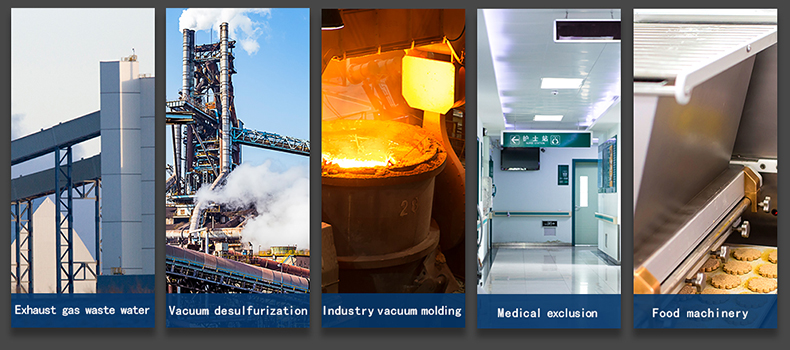

2BV series water ring vacuum pump is suitable for pumping out gas and water vapor. The suction pressure can reach 33mbar absolute pressure (97% vacuum degree). When the water ring vacuum pump works for a long time when the suction pressure is close to the limit vacuum (saturated steam pressure of working fluid), the cavitation protection pipe shall be connected to protect the pump. When used as a compressor, the maximum pressure is 0.26mpa (absolute pressure). 2BV series water ring vacuum pump is a new generation of energy-saving products. With excellent performance and many advantages, it will comprehensively replace SK and 2SK series water ring vacuum pumps and W, WY and WL series reciprocating vacuum pumps.

2BV2 and 2BV6 series water ring vacuum pumps / compressors are mainly used to extract explosive gases and work in various flammable and explosive environments. Their performance parameters are the same as 2BV2 and 2BV5 series.

2BV series stainless steel vacuum pump can be used in various occasions with high corrosion resistance requirements and high cleanliness requirements.

According to the working condition, all flow passage components of 2BV series stainless steel vacuum pump: impeller, disc, pump cover and pump body can be selected:

SUS304(0Cr18Ni9)

SUS316(0Cr17Ni12Mo2)

SUS316L(00Cr17Ni14Mo2)

And other stainless steel materials, pump shaft material: 2Cr13, SUS304 or SUS316L

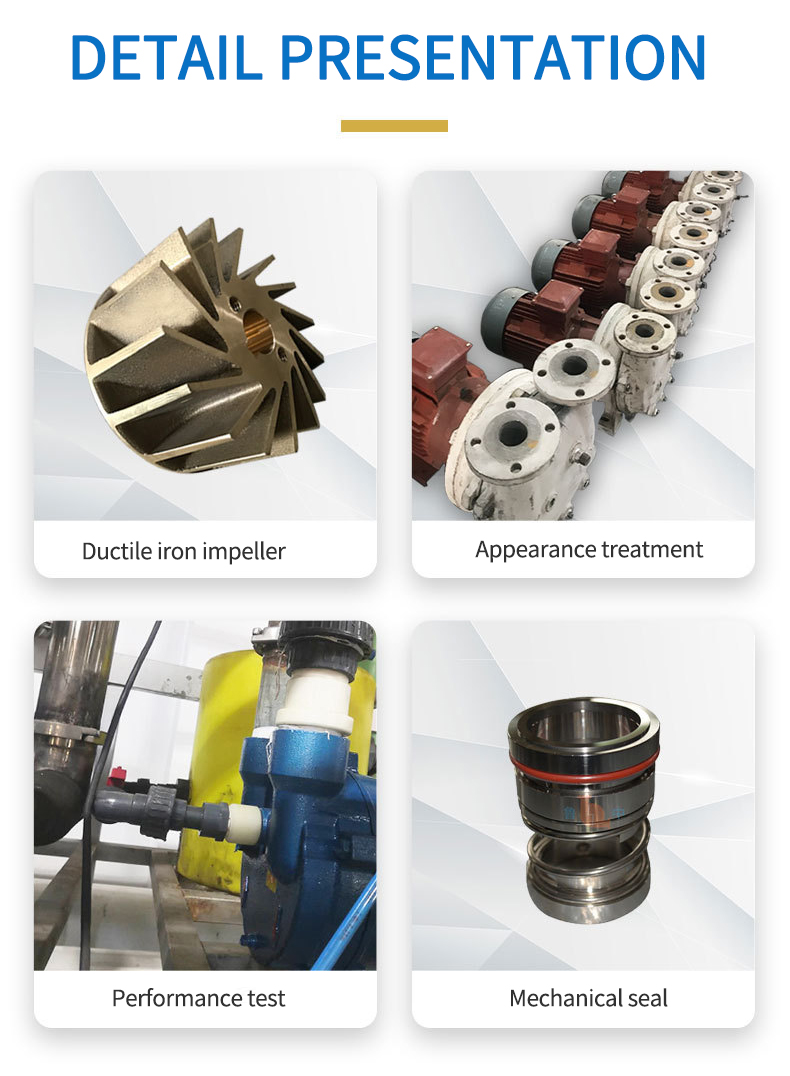

The mechanical seal adopts imported products, and the seal can be fluororubber or polytetrafluoroethylene

Main features:

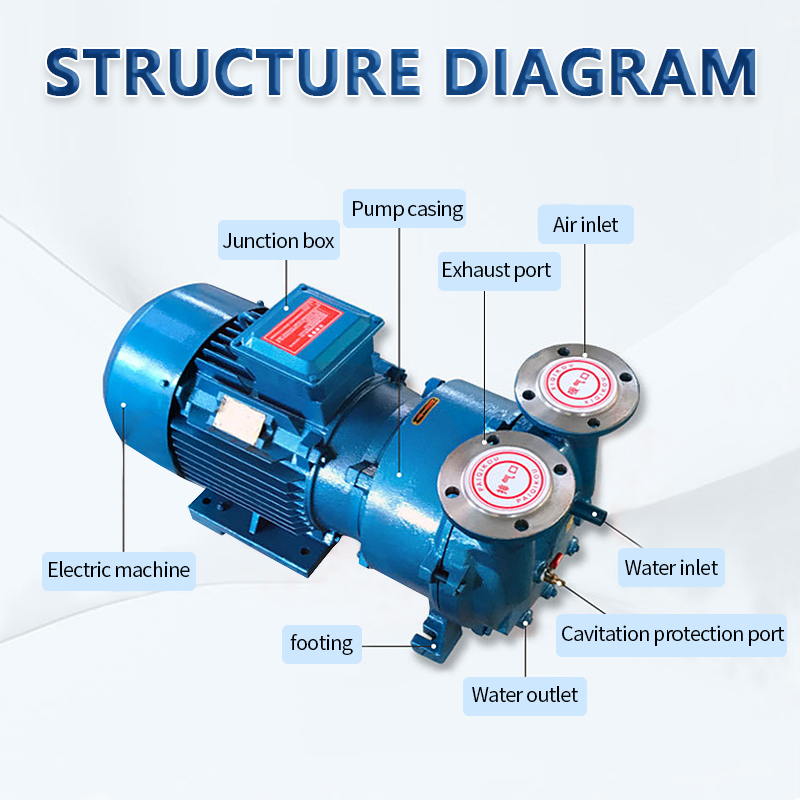

·Direct connection design of motor, saving space, easy installation and maintenance.

.All imported mechanical seals are used as standard configuration.

·All are equipped with cavitation protection pipe interfaces. If working under the limit pressure, opening the cavitation protection pipe interface (or connecting with the separator) can eliminate the cavitation sound and protect the pump under the condition of ensuring the suction effect to the greatest extent.

All 2BV series are equipped with stainless steel impellers as standard, and all 2BV2 series are equipped with stainless steel discs / impellers. High strength, durable, and improve the corrosion resistance of the pump. If all flow passage parts are made of stainless steel, they can work in a more harsh environment.

The unique flexible exhaust port design will not produce over compression, ensuring the best efficiency of 2BV within its performance range.

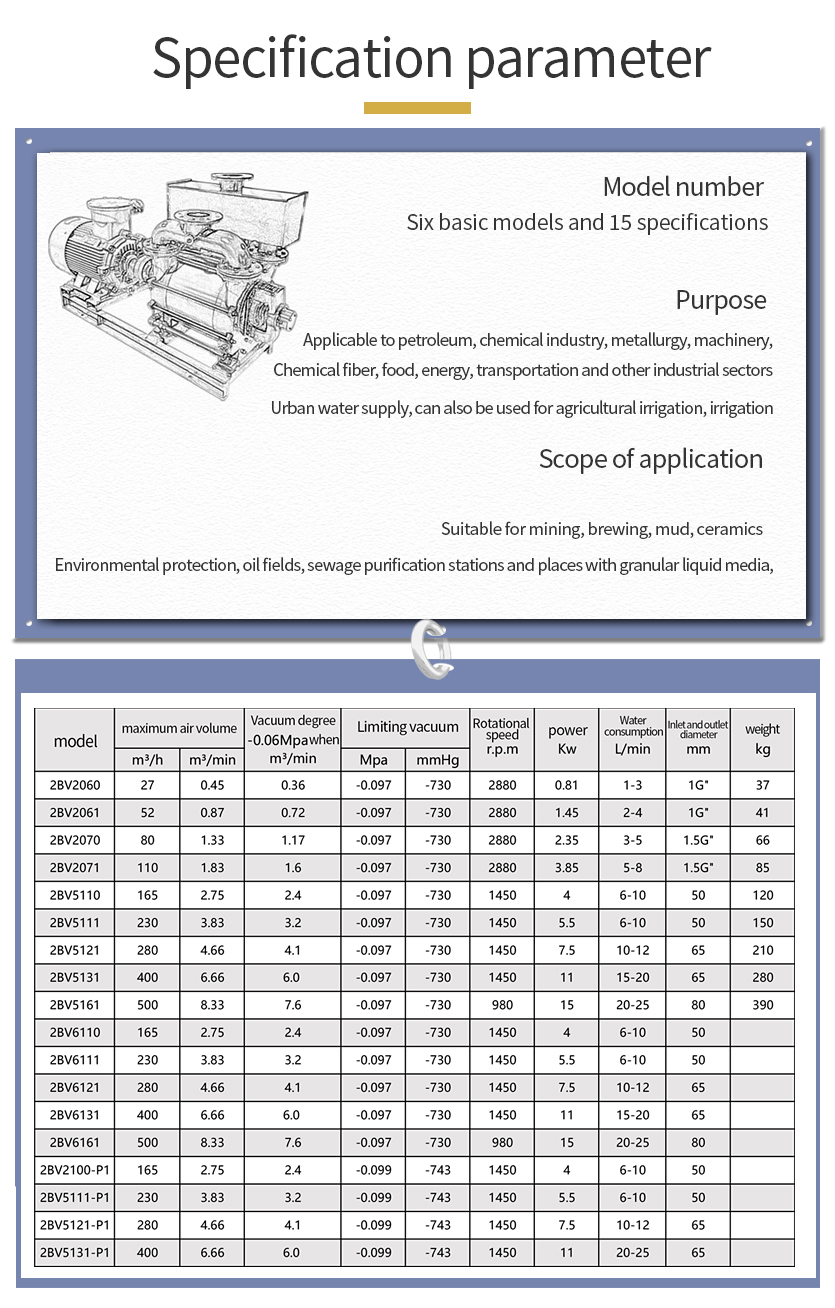

Parameter

After-sales instructions

After placing the order, please contact the salesperson to provide you with the installation plan as soon as possible. Please construct the foundation according to the dimensions on the foundation drawing.

2. Before installing and using the equipment, please carefully read the product installation and operation manual. If you have any questions, please call our 24-hour service hotline at 400-8570-567 or 13506440087. We will have professional technical personnel to coordinate with you.

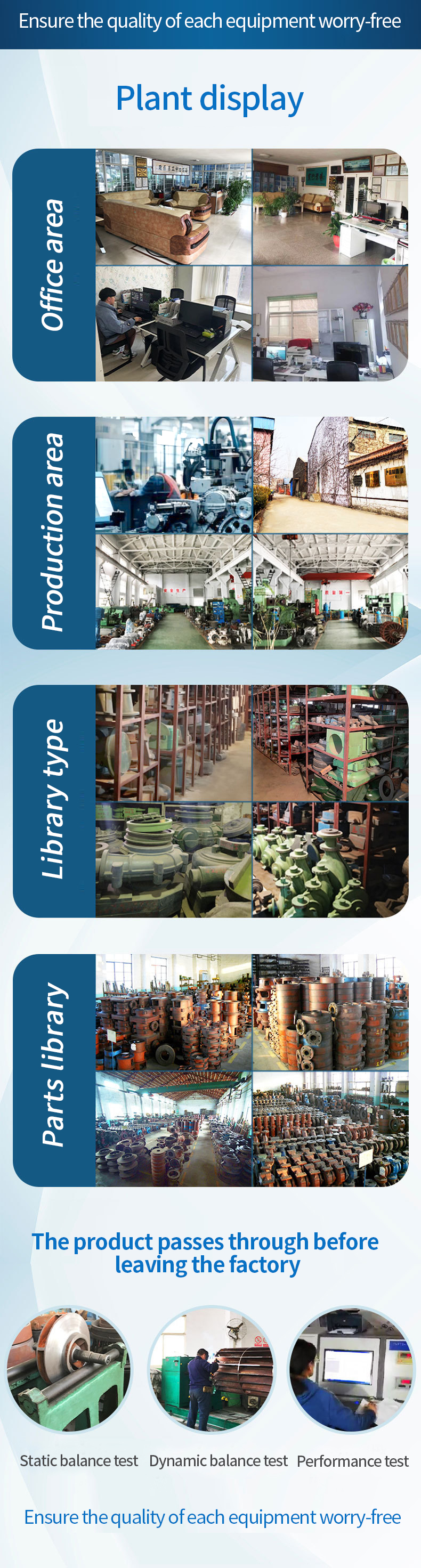

3. Before leaving the factory, the equipment undergoes a water and pressure test. If there is a small amount of water stored in the pump and it is installed and used in colder areas, please ensure that the storage and installation environment of the pump will not cause the water in the pump to freeze. Improper storage causing pump damage will be the responsibility of the user. Please empty the equipment and pipelines in a timely manner when not in use in winter to avoid damage caused by frost

4. Before using the pump, please ensure that the power supply voltage is stable, there is a protective device (which can be matched with a control system), the environment is dry, and the pipeline valves are installed properly. If you have any questions about installation and use, you can call our factory's service hotline. Any damage to the pump caused by improper installation or use shall be the responsibility of the user.

6. It is recommended that you install a filtering device on the imported pipeline and regularly clean it to ensure the reliability and service life of the pump operation

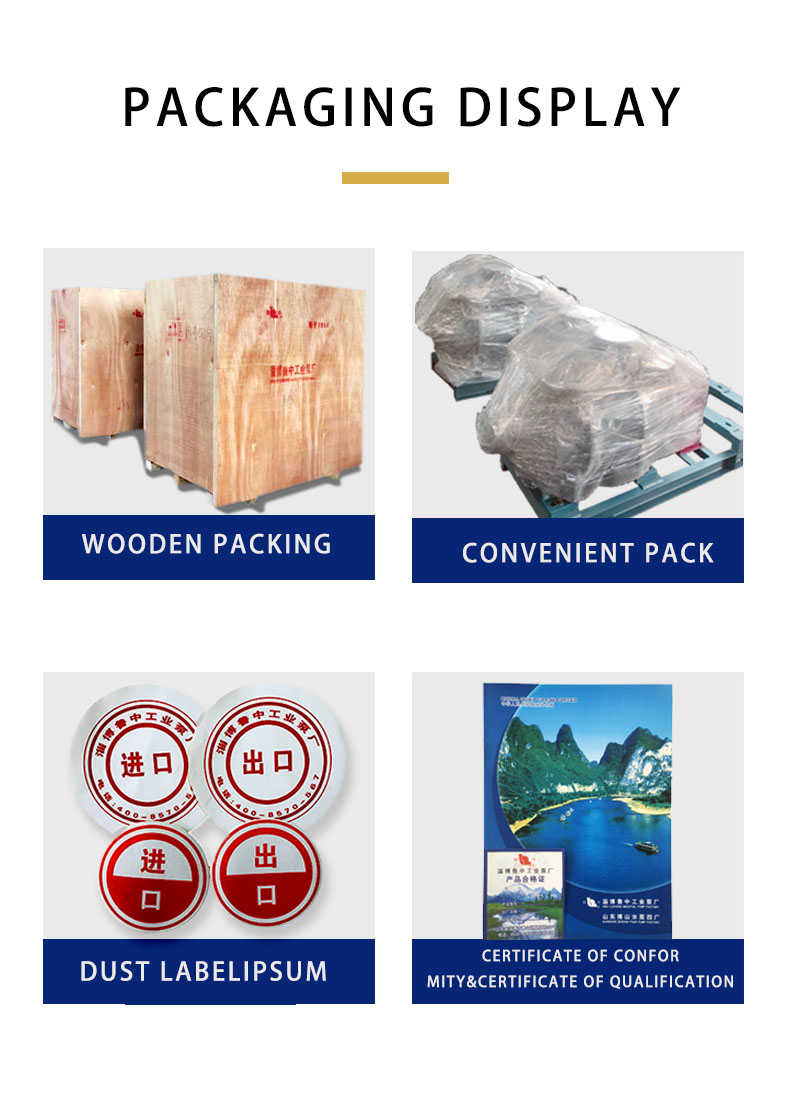

Receiving reminder

Dear customer, please check if the packaging of the goods is damaged upon receipt, and if the products, manuals, certificates of conformity, accessories, etc. are complete. If there are any abnormalities, please take photos immediately and contact the customer service manager. Please make sure to sign for it in person. Any loss or damage to the goods caused by not signing for it or not inspecting the goods will be the sole responsibility of the recipient.